Melt Pumps

|

eprotec melt-pumps for extrusion and compounding

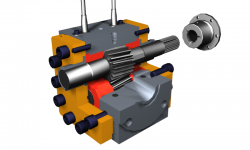

eprotec's melt-pumps (extrusion pumps, metering pumps or gear pumps) are installed in all applications in extrusion and compounding of plastics. Melt pumps are used to build up constant pressure and ensure constant output. The extruder screw is relieved, this enables a higher output power and increases the flexibility in different applications. Smooth, efficient and constant pumping of plastic melt through extrusion-die guarantees constant product quality and dimension. eprotec also offers its melt pumps together with a drive unit and controller.

eprotec's melt-pumps (extrusion pumps, metering pumps or gear pumps) are installed in all applications in extrusion and compounding of plastics. Melt pumps are used to build up constant pressure and ensure constant output. The extruder screw is relieved, this enables a higher output power and increases the flexibility in different applications. Smooth, efficient and constant pumping of plastic melt through extrusion-die guarantees constant product quality and dimension. eprotec also offers its melt pumps together with a drive unit and controller.

The retrofitting of extrusion lines with melt-pumps brings several advantages. Firstly, it ensures a constant throughput, which is crucial for achieving dimensional stability in the extruded product. By eliminating fluctuations in the extrusion process, the melt-pump guarantees a consistent output, reducing the risk of variations in product dimensions.

Additionally, the installation of a melt-pump often leads to higher output from the extrusion line. As the melt-pump takes over the pressure build-up, the screw can operate at a higher speed, increasing the overall production capacity. This improved efficiency allows for increased output without compromising product quality.

Furthermore, melt-pumps also contribute to improved process control. By separating the tasks of pressure build-up and material conveying, the extrusion process becomes more stable and controllable. This enables operators to fine-tune the process parameters and optimize production conditions, resulting in better quality products and reduced waste.

Retrofitting of extrusion-lines with melt-pumps leads primarily to a constant throughput. This is a requirement for dimension stability of extruded product. Retrofitting with melt-pumps leads mostly to higher output of extrusion-line. When a melt-pump is installed in extrusion-line the screw is not anymore responsible for the full pressure build-up.

Specifically designed for application:

eprotec melt-pumps are designed precisely for every application. According viscosity, throughput, processing temperature the pump-size, surface coating, tolerances e.g. are determined. Type and amount of fillers determine specific surface coating and bearing materials.