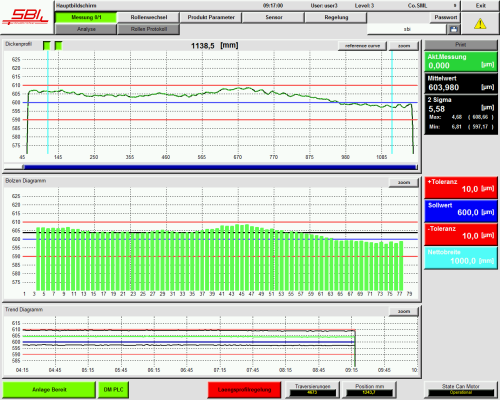

Inline thickness gauging (inline thickness monitoring):

On main screen of thickness measurement system the thickness of a film or sheet is displayed over width and over bolt-number of extrusion-die. Set tolerance-values are shown in red, production out of these tolerances will cause an alarm. This gives operator chance to adjust extrusion-die early enough and operator sees quickly on which bolt the extrusion-die needs readjustment. Corresponding bolt mapping calculates also neck-in in the edge region of the plastics film. History of last 24 hours is shown also on the main screen: Trend diagramm shows thickness average, minima and maxima as well as set tolerances.

In thickness profile diagram "thickness over width" are shown 4 graphs: set value (blue), actual measured thickness profile (green), average over last 5 measuring scans (black), "frozen" reference profile (grey). Actual thickness profile can be frozen as a reference profile, this shows the operator the success of thickness adjustment on the extrusion-die. This reference profile can be deleted, stored and reloaded at any time.

For closer inspection you can enlarge areas in the diagrams. Of course there are a number of additional screens available for displaying various parameter for extrusion (histories, quality parameters, production parameters like manufactured running meters, weight, running meters on actual roll, weight on actual roll e.g.)

With all SBI inline thickness gauges you can control the thickness average during extrusion (length profile control), if a connection to downstream is possible.

main screen of inline thickness gauge